Factory Strength

Why Choose Us

- Strong Factory Strength

- Innovative R&D Design Team

- Fast Sample with Quality Assurance

- Agile Production Process

- Strict Quality Control

- Stable Supply Chain Management

Factory Strength

Rainbow Touches Year

- 18 years garment production experience

- 13 years export experience

Scale and Equipment

- 8,000m2

- Guangdong factory and Hubei factory

- Approx 60 sets of Lockstitch Machine

Main Products

- T Shirts/tank tops/ hoodies & sweatshirt /shorts / trousers / jackets/ coats, etc.

- Good at knitted/woven clothing

- Provide 900styles new designs per month

Factory Output

- 110k pcs/monthly

- Produced 163 styles bulk orders one month

Workers

- 100+ workers

- 8 paper pattern master with 25 years experience,

Certification

- SGS/Intertek/BSCI.

Guangdong Factory

Hubei Factory

Production Equipment

Hot Press Machine

Hot press is commonly used to create prints and graphics on garments and textiles such as t-shirts, tank top,shorts, etc.

Digital Printing Machine

Digital printing machine uses ink-jet or dye-jet technology to accurately print patterns onto clothing through computer-controlled movement of the print head and ink jets. It enables high-quality, high-resolution pattern printing with greater design freedom.

Semi-automatic Screen Printing Machine

The semi-automatic screen printing machine is to manually operate the squeegee to scrape the ink paste evenly across the screen template, so that the ink paste penetrates the screen and prints patterns and designs. Semi-automatic screen printing machines are suitable for small batch production and custom printing needs.

Embroidery Machine

The embroidery machine can perform embroidery operations automatically, and embroider according to pre-designed patterns and programs, and can realize complex patterns and multi-color embroidery.

Electric Cutting Machine

Electric cutting machine is a device that uses electricity to cut fabrics and textiles. It usually has an automated cutting function that can quickly and accurately cut out the desired fabric shape. This equipment improves the speed and accuracy of cutting. sex, saving time and labor costs.

Laser Cutting Machine

The laser cutting machine uses the high energy density of the laser beam to cut fabrics without traditional knives. The laser cutting machine has very high precision and flexibility, and can realize complex cutting and embroidery patterns. It is suitable for all types of fabrics and reduces cutting errors and fabric waste.

Automatic Button Feeder

The purpose of the automatic button feeder is to fasten and efficiently button garments. For mass production, the automatic button feeder can greatly improve production efficiency, reduce labor costs, and ensure the consistency and accuracy of button sewing. This can help us complete orders faster, meet customer needs, and improve factory production capacity and competitiveness.

Desktop Needle Detector

Metal Needle Detector can help to find and remove metal impurities in time, such as needles, needle tubes, needle pieces, buttons, etc., improve product quality and safety, and ensure that products meet the requirements of regulations and standards.

R & D Design Capabilities

Pattern Design Capability

- Creates unique and personalized patterns in various styles, using the latest software and hand-drawing techniques.

- We consider factors like complexity, size, and fabric to ensure successful production.

- Technical drawings are provided for the production process.

Modeling Capability

- Use 3D software to create realistic and detailed clothing samples quickly.

- With 3D models, you can evaluate designs and avoid issues before production, saving time and cost.

Reasonable Integration of Resource Supply Chain

- There are factories in Guangdong and Hubei with an integrated supply chain.

- Stay updated with streetwear trends and product information, enabling us to quickly understand required fabrics and processes to provide production samples.

Professional Designers

- Team professional designers from top universities in China and part-time overseas designers, collaborating with third-party design companies such as ASOS, PALACE SKATEBOARDS, and ZANEROBE.

- Strong R&D and innovation capabilities and are always exploring the dark streetwear field.

- If you are a designer with a passion for streetwear brands, welcome you to join us.

Pattern Design Capability

Our design team has extensive experience and professional knowledge, providing you with a variety of pattern design services in different styles. Using the latest design software and tools, we create unique and personalized patterns quickly. Our designers use design software and hand-drawing techniques to create patterns and convert them into technical drawings required for the production process. We consider factors such as complexity, size, and fabric of the pattern to ensure that the final clothing pattern meets expectations and can be successfully produced.

Modeling Capability

Our modeling team has mature technology and experience, able to quickly and accurately model and produce realistic and detailed samples. We use 3D modeling software and technology to present the most realistic effects for your better understanding of your design. We provide three-dimensional solid models, which can visually display the appearance, details, and structure of clothing, helping you better understand and evaluate design solutions. We use computer-aided design (CAD) software to make 3D models and adjust and modify them according to your needs. Through modeling, we can avoid problems and save time and cost in actual production while also preparing samples and mass production more quickly.

Reasonable Integration of Resource Supply Chain

We have factories in Guangdong and Hubei, with numerous processes and fabrics, and have integrated an entire supply chain. In terms of product information, we have two business units in South China and Central China, which can grasp the information on the popular clothing industry in China and often participate in domestic and foreign exhibitions, paying attention to product information such as fashion magazines such as Harper‘s Bazaar. Once you provide the product, we can quickly understand the required fabrics and processes and provide you with the processes and fabrics for production samples immediately.

Professional Designers

We have professional designers from Wuhan Academy of Fine Arts, Wuhan Textile University, and Guangdong Design Institute, with strong professional academic and aesthetic abilities. In addition, we also recruit part-time overseas designers to give us greater advantages in R&DDesign Ability. If you are a designer with dreams and love for streetwear brands, you can alsojoin usand collaborate with us. We cooperate with third-party design companies overseas, such as ASOS, PALACE SKATEBOARDS, ZANEROBE, and other streetwear brand designers, always working with the best people, and have strong R&D and innovation capabilities. From the perspective of fabric, auxiliary materials, technology, talent, information resources, and customer market expansion, we have been exploring the streetwear field and look forward to working with you.

Fast Sample with Quality Assurance

Quick Response

- Swiftly respond to customer demands by providing samples in the shortest possible time as we specialize in streetwear clothing customization for more than 15 years.

- Deep understanding of market changes and customer needs allows us to get started immediately.

Efficient Quality Assurance

- Place a great emphasis on quality during the design and production of our samples to ensure that the final product meets your requirements.

- Equipped with advanced tools such as CAD sampling machines and digital cutting machines, we are able to quickly and accurately produce samples that meet your specifications while optimizing our workflow and timelines.

Customization

- Create product samples based on your Tech Pack or design requirements.

- If you don't have a design, we can use retail products or local store references to create one.

- We can also purchase and deliver various samples and fabrics from the Chinese market to improve R&D development.

Experienced Team

- Our experienced team has over ten years of experience in the streetwear customization industry.

- Understand market trends and customer demands and apply this knowledge to our work to ensure that we deliver the highest quality and most optimized service possible.

Production Process

Paper Pattern Making

- Based on the design drawings you provide or those designed by our designers, we will make paper patterns. This step is to ensure that the size, style, and pattern of the produced clothing are consistent with your requirements.

Procurement

- After confirming the paper patterns, we will purchase the required raw materials according to the order. This includes fabrics, accessories, and other materials.

- We will select high-quality, environmentally friendly, and compliant materials to ensure the quality of the produced clothes.

Cutting

- After purchasing the raw materials, we will proceed with cutting. We will cut the fabric according to the paper patterns and tailor them according to your requirements.

- After cutting, we will classify and organize the fabrics.

Sewing

- After cutting, we will sew the fabrics. We will sew according to the order requirements, using high-quality sewing machines and threads to ensure the quality and effect of the clothes.

Quality Inspection

- After the clothes are sewn, we will conduct a quality inspection.

- We will strictly inspect the pattern, size, workmanship, fabric, accessories, and other aspects of the clothes to ensure that the quality meets the standard.

Ironing

- After passing the quality inspection, we will iron the clothes. This process is mainly to make the clothes more smooth and perfect.

Quick Response

- After ironing, we will package the clothes. We will package according to your requirements to ensure that the products can be transported intact to you.

Production Process

Paper Pattern

1

Cutting

2

Sewing

3

Inspection

4

Ironing

5

Inner Packing

6

Outer Packing

7Production Related Key Areas

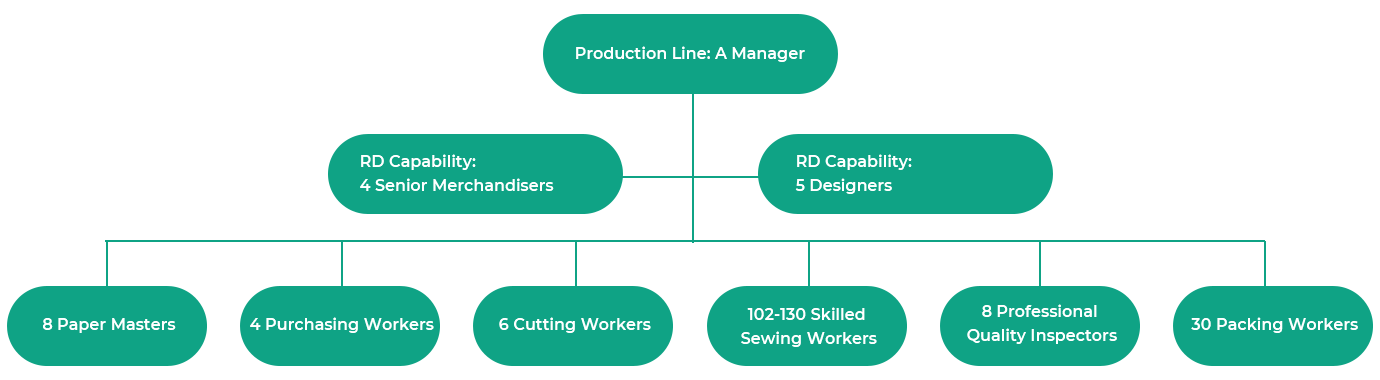

Production Line Personnel Structure

Quality Control

Raw Material Inspection

- Check if the fabric meets the requirements, such as composition, weight, and hand feel.

- Check if the accessories such as zippers, buttons, etc. are complete and meet the quality standards.

Cutting Quality Inspection

- Check if the cutting is accurate, including size, shape, etc.

- Check if there are any defects in the fabric, such as holes, tears, stains, color yarns (especially for white garments), etc.

Sewing Quality Inspection

- Check if the stitching is neat, such as whether the thread ends are smooth, whether the bone position may burst, etc.

- Check the symmetry of each part, such as sleeve length, shoulder width, etc.

Processing Technology Inspection

- Check if the processing technology for accessories, printing, embroidery, etc. is accurate, such as whether the position is correct, whether the color is consistent, whether there are omissions in the process of using specialized machines, etc.

- Check if the pattern is clear and full, such as for snowflake frying and high-temperature ironing patterns, the finished product needs to be pulled hard to see if the fabric can withstand the force without tearing.

Finished Product Quality Inspection

- Check if the size and color of the finished product meet the requirements, and inspect in order from top to bottom, left to right, front to back.

- Check if there are any defects or damages in the finished product, such as uncut thread ends, uneven hemlines, etc.

Packaging Quality Inspection

- Check if the labels, hang tags, instructions, etc. are complete and meet the requirements.

- Ensure that the packaging, boxing, and strapping are firm to avoid damage.

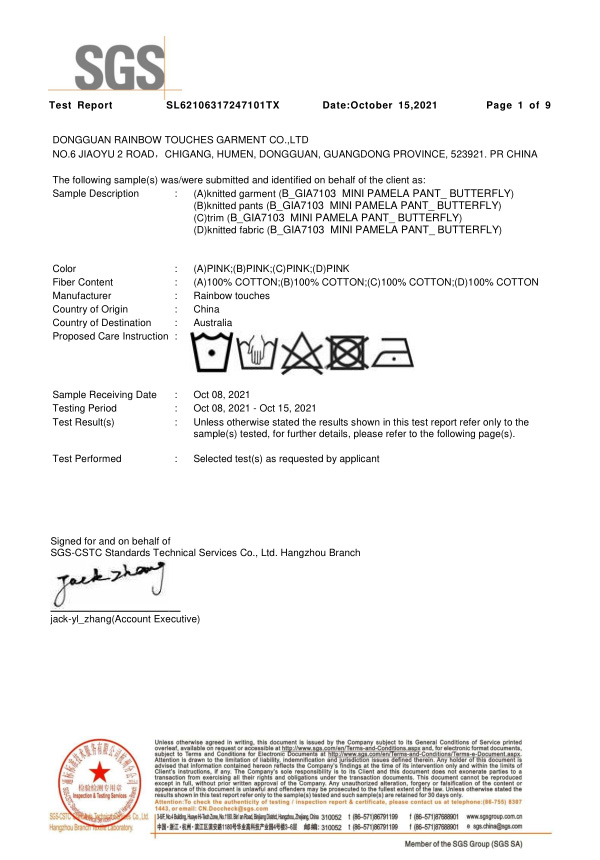

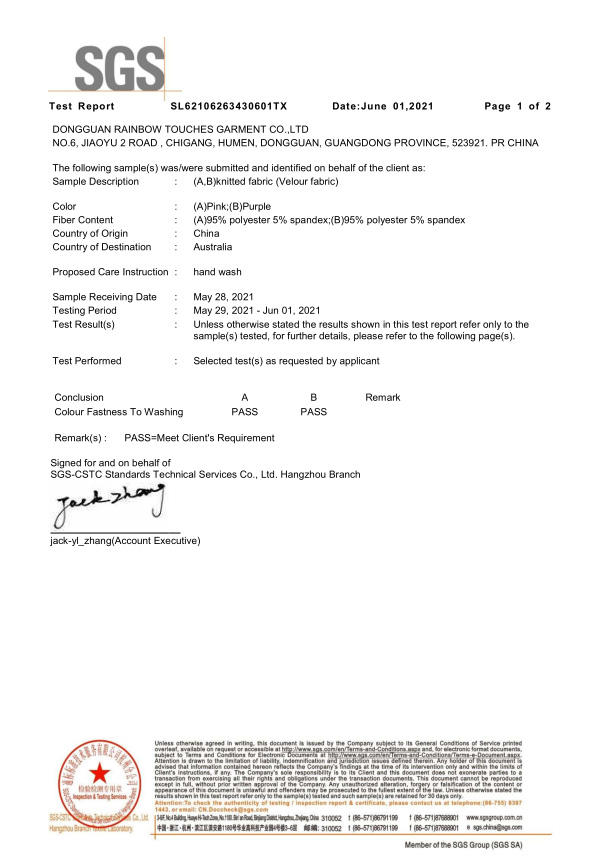

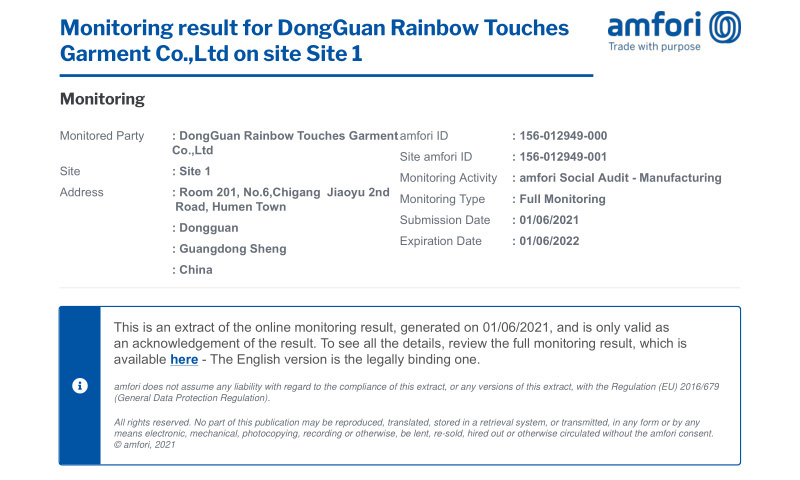

Our Certification

*BSCI certification is a social responsibility audit to ensure that our factories comply with labor regulations, pay attention to employee welfare and safety, and adopt sustainable production methods.

Product Certification

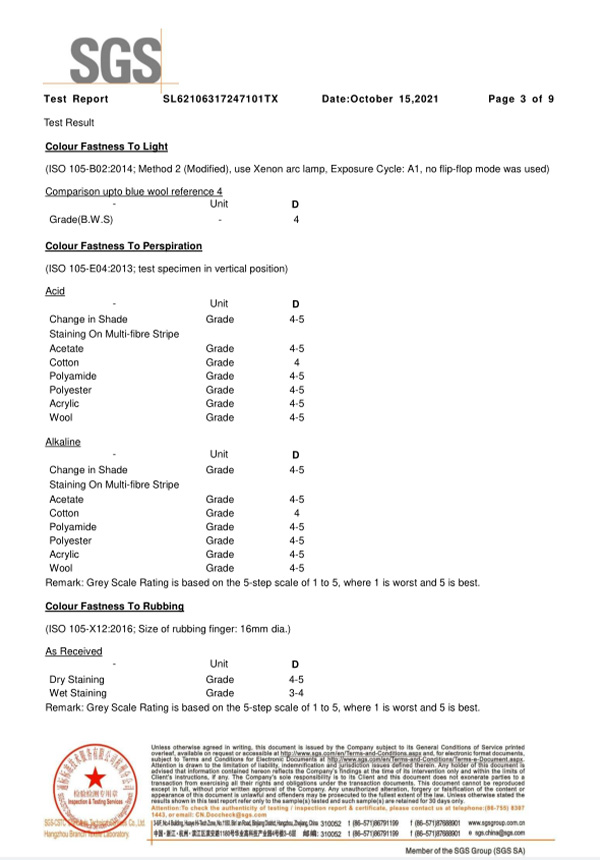

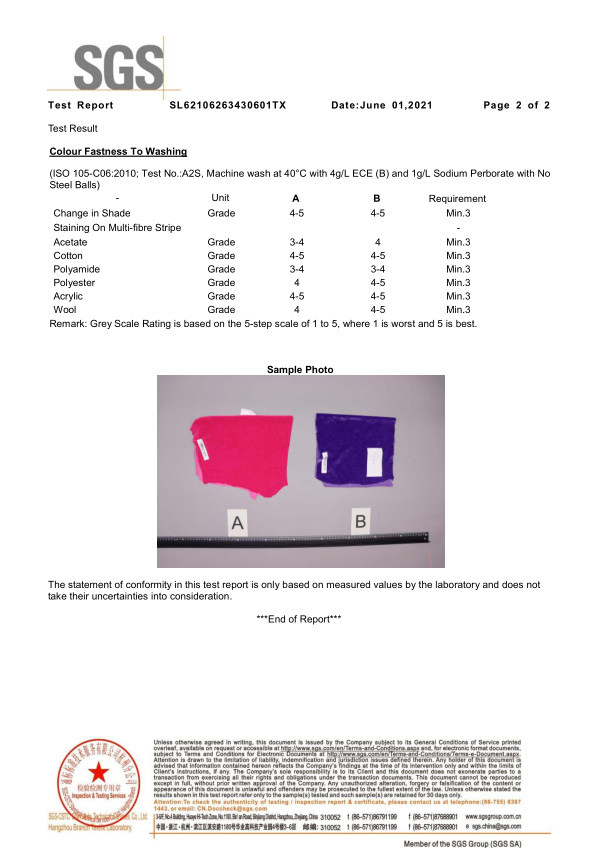

G Brand Hoodie Colour Fastness Test

We cooperate with G brand. The customer wants to customize a batch of high-quality hoodies. In order to ensure the color fastness and durability of the product, we actively propose to the customer to conduct a colour fastness test and entrust a professional organization to conduct the test. We chose a reputable testing agency, SGS, to perform the colour fastness test. They use standardized testing methods and equipment to evaluate the color fastness of the hoodies.

Test results show that our hoodies survived the fade test. The color fastness rating has reached the optimal level of 4-5, which proves that the dye of the product is strong and not easy to fade. This is a testament to the excellent quality and durability of the dyes and workmanship we use.

Our high attention to product quality not only focuses on innovation in appearance and design, but also ensures that the products can maintain bright colors and durability during use. We are willing to share such cases with our customers, and are ready to accept any other necessary testing and certification to ensure that our products meet the quality standards and meet the needs and expectations of our customers.

Supply Chain Management

Supplier Management

- Our suppliers include fabric, accessories, process assistance, packaging, transportation, etc.

- Establish long-term and stable cooperative relationships with high-quality suppliers and regularly evaluate and monitor their performance to ensure that their quality, prices, and services meet our standards.

Production Planning

- We ensure the efficient operation and timely delivery of production lines through detailed production planning and scheduling.

- Schedule and monitor each order in detail to ensure that each process is completed within the stipulated time, achieving the efficient operation of the production line.

Logistics Management

- We establish long-term cooperative relationships with logistics partners to ensure that their services and transport speeds meet our requirements.

- Timely grasp the transportation status of goods and ensure the safe and rapid delivery of goods to customers.

Inventory Management

- We plan the inventory of raw materials and components reasonably to avoid excessive inventory occupation of funds, reduce inventory costs, and ensure inventory accuracy and transparency.

Information Technology Construction

- We use information technology and software systems to manage and track the supply chain, including procurement, production, logistics, quality, and inventory information.

- Track and monitor every aspect of the supply chain in real-time and promptly handle exceptional situations to ensure the efficient operation and optimization of the supply chain.

Factory Core Value

Strict Quality: We always prioritize quality. We carefully select premium fabrics and materials, and rigorously control every step of the production process to ensure that our custom clothing possesses outstanding texture, comfort, and durability. We firmly believe that high-quality products are the foundation for building successful brands.

Innovative Design Team: Our design team is full of creativity and passion. We stay on top of trends and understand market demands. Through close collaboration with our clients, we provide professional design advice and customized solutions to ensure that each garment reflects a unique brand personality and fashionable style.

Confidential Collaboration: We highly value our clients' business confidentiality and brand image. We promise absolute confidentiality, strictly adhering to contract agreements and intellectual property laws to ensure that our clients' design and product information remains secure and undisclosed to third parties.

Flexible Customization: We offer flexible customization options, including OEM and Private Label services. Whether our clients require production based on their own designs or seek our professional advice, we are able to customize according to their specific needs and budgets.

Long-term Partnership: We are committed to establishing long-term partnerships with our clients. We care about their success and development, consistently providing high-quality customization services and growing together. We believe that a mutually beneficial and trusting partnership is the key to achieving win-win outcomes, whether our clients are brand owners, designers, importers, or entrepreneurs.

- Name

- Phone

- *Title

- *Content

Contact

- Contact Person:

Sina Lee

Sina Lee

- Email:

- sina@rainbowtouches.com

- Tel:

- +0086-13423110605 / +0086-0769-81519190

- ZIP Code:

- 523920

- WhatsApp:

- 8613423110605

- Skype:

- sinalee608

- WeChat:

- Sina-Lee

- Messenger:

- https://m.me/367304126798785

- LinkedIn:

- https://linkedin.com/in/streetwears

- Address:

- Room 1206, Building A1, Junma 1 Road, Chigang Community, Humen Town, Dongguan City, Guangdong Province, China

- Name:

- Sina Lee

- Tel:

+0086-13423110605

+0086-0769-81519190

- Email:

- sina@rainbowtouches.com

- WhatsApp:

- 8613423110605

- Skype:

- sinalee608